Empowering industries with real-time insights

Experience enhanced efficiency, superior quality, and data-driven decision-making with Pixact’s advanced inline measurement technology.

A brighter picture of your process

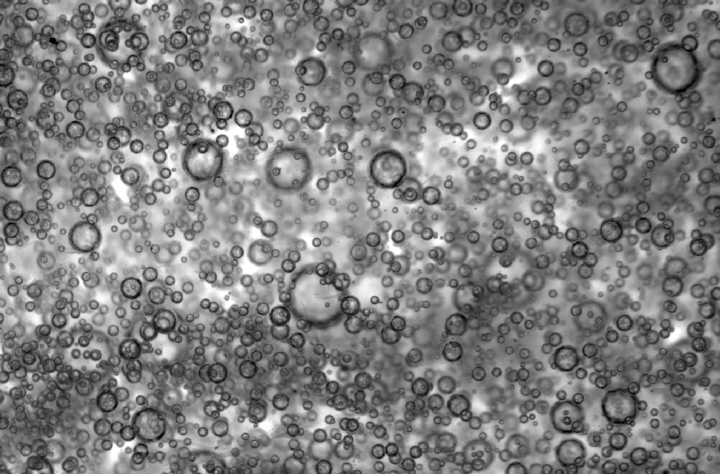

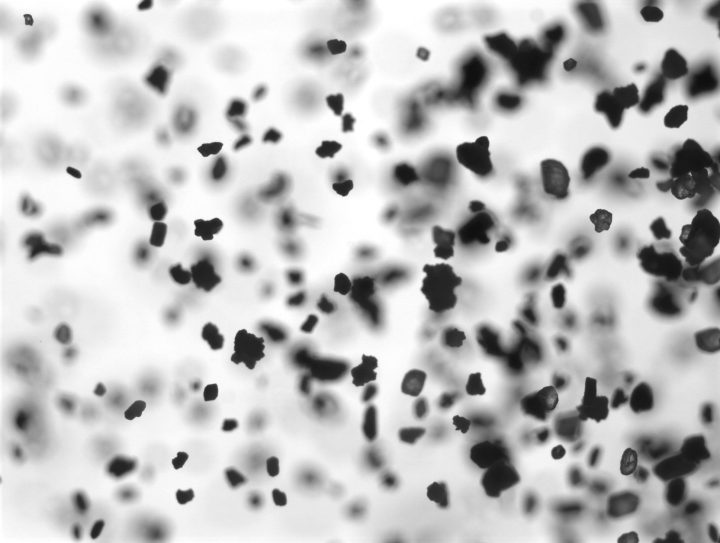

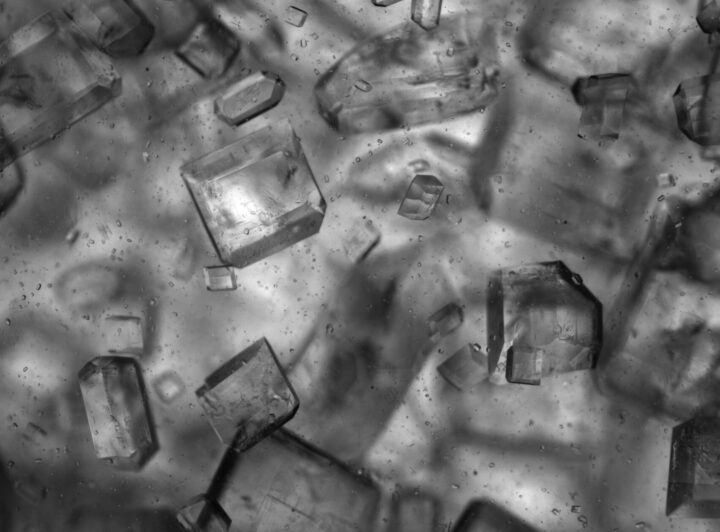

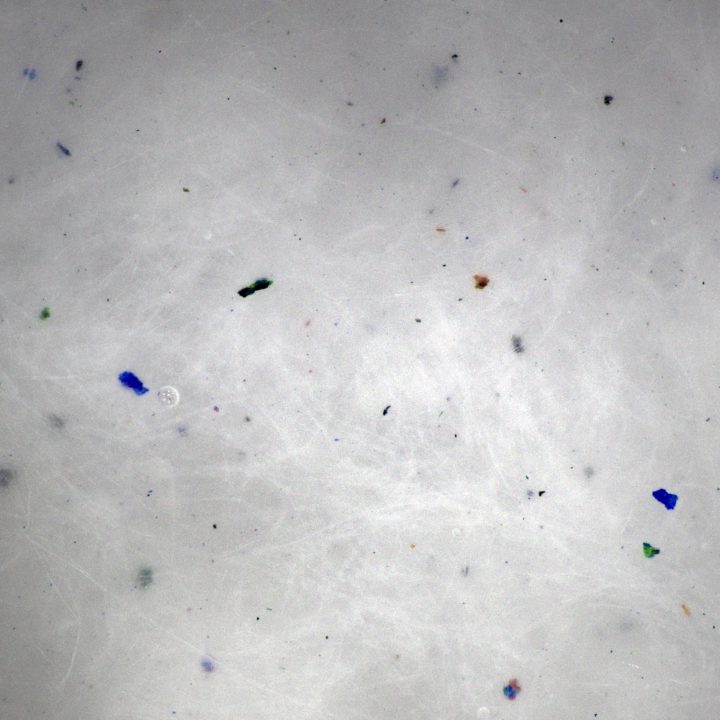

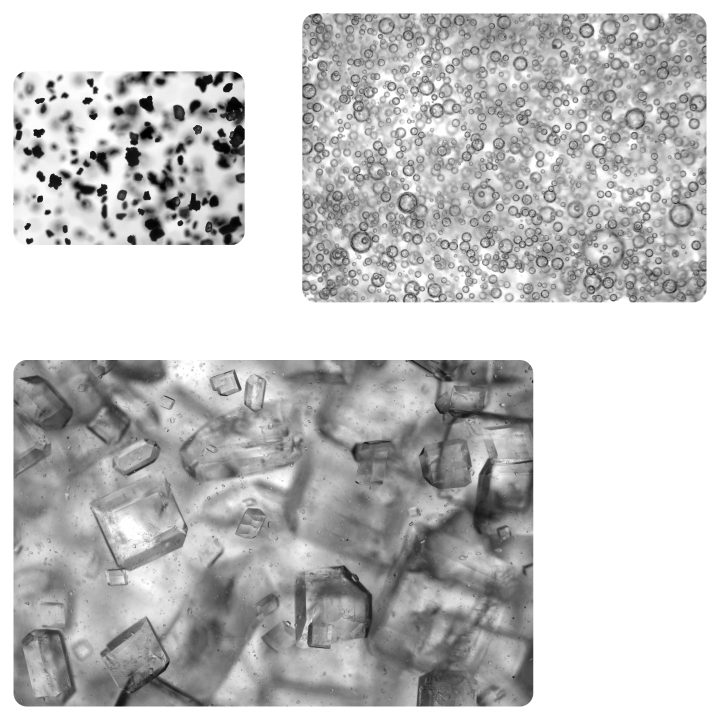

Pixact develops and supplies novel inline measurement technology based on optical imaging. Our mission is to provide new tools for the diagnostics of industrial processes involving particle-gas-liquid suspensions.

200+

Measurement systems delivered

200+

Measurement campaigns and trials

20+

Countries where we are operating

Historical moment for Pixact! – Opening celebrations of the joint venture in China

We are proud to announce the opening of our new joint venture in China together…